Achieving Optimal Performance: The Importance of Commercial Kitchen Hood Balancing

In the bustling world of commercial kitchens, where the sizzle of pans and the aroma of cooking food fill the air, maintaining a well-balanced environment is crucial. Among the many components that contribute to a smoothly functioning kitchen, the commercial kitchen hood stands out as a pivotal element, ensuring safety, efficiency, and regulatory compliance. However, achieving optimal performance from these hoods requires meticulous attention to detail, particularly in the realm of air balancing. Let’s delve into the significance of Commercial Kitchen Hood Balancing and explore the nuances of Air Balancing Hoods.

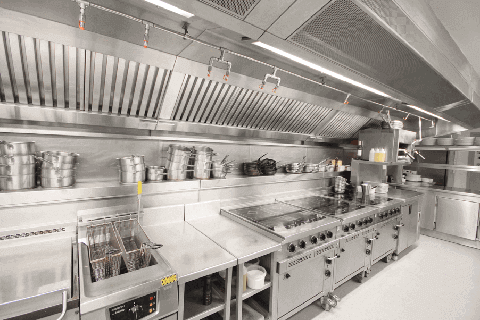

The Heartbeat of the Kitchen: Commercial Kitchen Hoods

Commercial kitchen hoods serve as the primary defense against the buildup of heat, smoke, grease, and odors in kitchen spaces. They function by capturing and extracting airborne contaminants generated during cooking processes, thereby maintaining a clean and safe environment for kitchen staff and patrons alike. Additionally, these hoods play a vital role in fire prevention, as they help eliminate flammable particles and reduce the risk of grease fires.

The Role of Balancing in Commercial Kitchen Hoods

While installing a commercial kitchen hood is a significant step toward ensuring kitchen safety and functionality, its effectiveness hinges on proper balancing. Balancing involves fine-tuning the airflow within the hood system to achieve optimal performance. This process encompasses several key aspects:

- Airflow Distribution: Properly balanced hoods ensure that airflow is distributed evenly across the cooking area, effectively capturing contaminants and preventing them from escaping into the kitchen or adjacent spaces. This balance is essential for maintaining a comfortable working environment and preventing the buildup of heat and odors.

- Capture Efficiency: Balancing the airflow ensures that the hood effectively captures contaminants at their source, whether it’s a stovetop, grill, or fryer. Improper balancing can result in inadequate capture efficiency, allowing smoke, grease, and other pollutants to escape into the kitchen, posing health risks and potentially violating safety regulations.

- Energy Efficiency: Well-balanced hoods operate more efficiently, consuming less energy while maintaining optimal performance. By fine-tuning airflow rates and minimizing air leakage, businesses can reduce energy costs and environmental impact without compromising on kitchen safety and cleanliness.

Understanding Air Balancing Hoods

One of the critical components of Commercial Kitchen Hood Balancing is Air Balancing Hoods. These specialized hoods are designed with features that facilitate precise control over airflow, ensuring optimal performance in demanding kitchen environments. Here are some key aspects of Air Balancing Hoods:

- Variable Air Volume (VAV) Technology: Air Balancing Hoods often incorporate VAV technology, which allows for the adjustment of airflow rates based on cooking activity and contaminant levels. By dynamically modulating airflow, these hoods maintain consistent capture efficiency while minimizing energy consumption.

- Pressure Differential Control: Air Balancing Hoods may also utilize pressure differential control systems to maintain the desired airflow balance within the kitchen space. These systems monitor pressure levels and adjust airflow accordingly to prevent negative pressure issues, such as backdrafting and smoke spillage.

- Integrated Sensors and Controls: Many modern Air Balancing Hoods feature integrated sensors and advanced control systems that continuously monitor environmental conditions and adjust hood performance in real-time. These smart technologies enhance efficiency, safety, and compliance with regulatory standards.

The Benefits of Proper Hood Balancing

Investing in proper Commercial Kitchen Hood Balancing offers a myriad of benefits for businesses in the foodservice industry:

- Enhanced Safety: Well-balanced hoods minimize the risk of fire hazards and airborne contaminants, ensuring a safer working environment for kitchen staff and patrons.

- Improved Air Quality: By effectively capturing and removing smoke, grease, and odors, balanced hoods help maintain high indoor air quality, enhancing comfort and satisfaction for occupants.

- Regulatory Compliance: Properly balanced hoods ensure compliance with local building codes, fire safety regulations, and health standards, reducing the risk of fines, penalties, and legal liabilities.

- Energy Savings: Optimal hood balancing reduces energy consumption and operating costs, offering long-term savings for businesses while minimizing environmental impact.

Conclusion

In the fast-paced world of commercial kitchens, achieving optimal performance from hood systems is essential for ensuring safety, efficiency, and compliance. Proper Commercial Kitchen Hood Balancing, particularly with the integration of advanced air balancing technologies, plays a critical role in achieving these objectives. By prioritizing hood balancing and investing in innovative solutions, businesses can create healthier, safer, and more sustainable kitchen environments for their employees and customers alike.

Comments

Post a Comment